DESIGN OF LOGISTIC SYSTEM SUPPORTED BY DIGITAL FACTORY

Jozef HNÁT *, Beáta FURMANNOVÁ **

AbstractThis paper is focused on application of digital factory tools in the logistics planning process. We have used software Tecnomatix Process Designer which represents complex PLM solution for digital factory. Environment of logistics module, main workflow and basic functionalities of this module are described here. 1. INTRODUCTIONDesign of the logistics system represents an important part of the production system design. Production can`t exist without supply of material from the warehouse to the workplace and transport of products from the workplace to the warehouse of finished products. Therefore it is necessary to create appropriate routes, to define appropriate transported quantities, to choose the technology to be used in warehouses for transport, etc. New technologies are developed rapidly and enterprises have to think about their implementation into the strategy (which technologies to use and in which specific areas to increase company`s KPIs). Tecnomatix Process Designer is a digital manufacturing solution for manufacturing process planning in a 3D environment. Process Designer is a major enabler of speed-to-market by allowing manufacturing organizations to bridge product and process design with integrated authoring capabilities that leverage digital product development resulting in faster launch and higher production quality.

2. TECNOMATIX PROCESS DESIGNER - LOGISTICSTecnomatix Process Designer facilitates the authoring and validation of manufacturing processes from concept and detailed engineering through production planning. Process Designer enables manufacturers to develop, capture and re-use process plans. Furthermore, process design teams can compare alternatives to develop and select best manufacturing strategies that meet specific business requirements. In a 3D virtual environment, Process Designer is a collaborative platform that enables distributed enterprise teams to evaluate process plans and alternatives, optimize and estimate throughput and costs, plan for variants and changes and coordinate production resources.

Part of this solution is the Logistics module which provides users with a basic data model of logistic objects, allowing them to build logistics-specific planning projects and manage the relevant data.

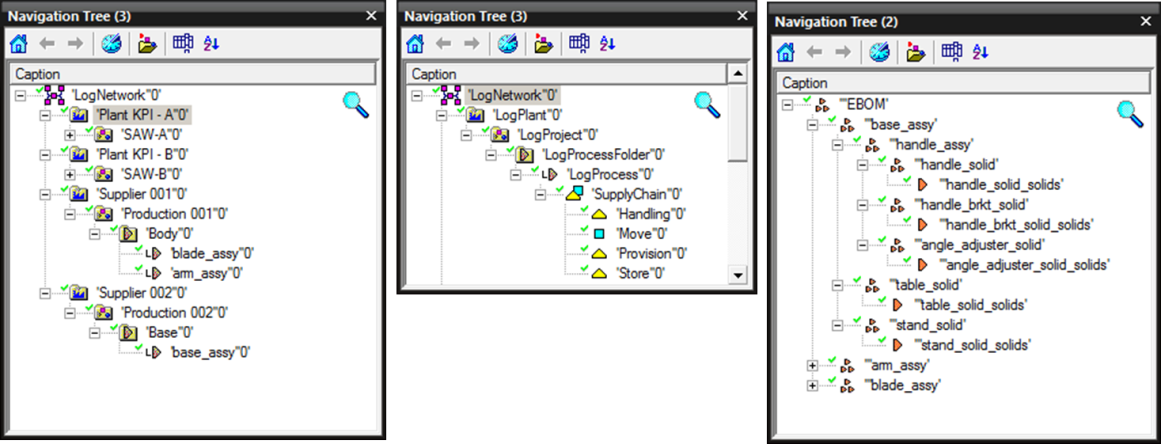

In the first phase we can start with network planning. In this phase logistics planners are allowed to define logistic networks and to calculate production rates per part family. This requires to use following steps:

- Setup the network structure.

- Setup the part structure (BOM).

- Setup one resource per logistic plant.

- Assign the resource which represents the logistic plant to the logistic plant of the network structure.

- Assign the produced parts to the logistic plant project and define the production rate.

- Create part families aically out of the BOM. One part family is created for each part in the BOM, and the relevant part is assigned to the part family. Alternatively, the part families can be defined in a library and copied below the logistic project. Based on the information you defined, the system calculates the required transportation relations between the plants. The calculated transportation relations include the calculated number of products and required parts.

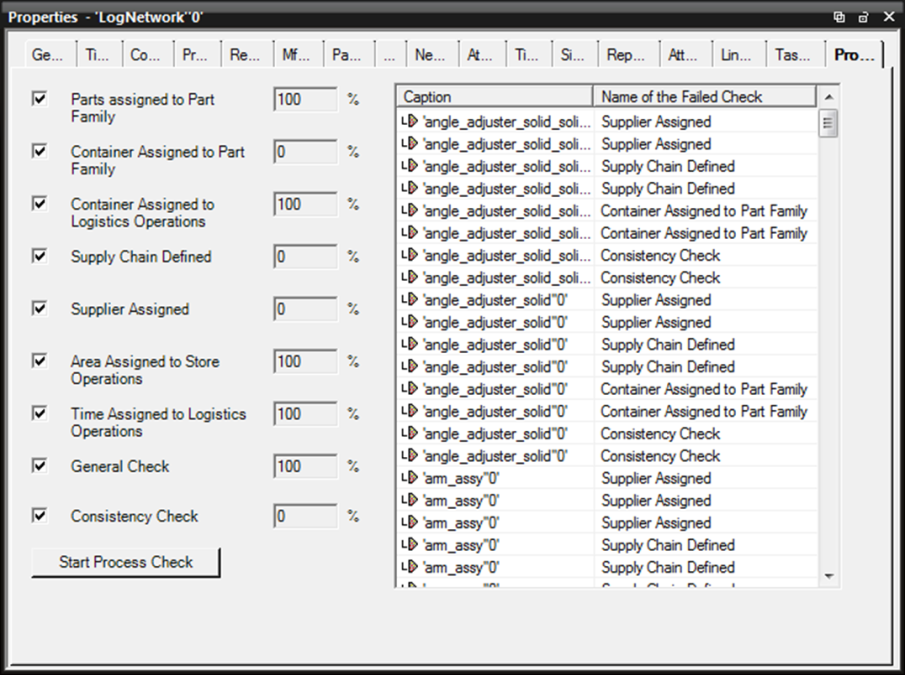

Logistics planners can open the Process Check tab (Fig.2.) to view progress of the logistic planning. The Process Check tab offers the following predefined checks:

- Parts assigned to LogProcess: Is there at least one part assigned to the LogProcess object?

- Container assigned LogProcess: Is there exactly one Container assigned to the LogProcess object?

- Container assigned to logistics operations: Is there exactly one Container assigned to the Move/Store operations of the supply chain of the LogProcess?

- Supply Chain defined: Is there a supply chain defined for the LogProcess?

- Supplier assigned: Is a supplier assigned to the LogProcess?

- Areas assigned to store operations: Are there LogAreas assigned to the store operations of the supply chain?

- Times assigned to logistics operations: Are there times assigned to the logistics operations (do all logistic operations of the supply chains have an allocated time > 0).

- General check that assigned container, supplier, areas, etc., are from the correct defined library: The system checks whether all assigned resources of the following types - LogArea, LogContainer, Supplier, Vehicle, Transporter, SupplyChains (for linked supply chains) belong to the respective library of the plant, under which the LogProcess resides. The libraries are taken from fields such as LogPlant,LibrarySuppliers, etc.

- Consistency check to verify the logistics plan against the production plan to find any inconsistencies. The check is based on the use of the same parts and logistics areas by both production planning and logistics planning. A logistics plan is consistent if the parts and the corresponding logistics areas are assigned to the same station as in the production plan.

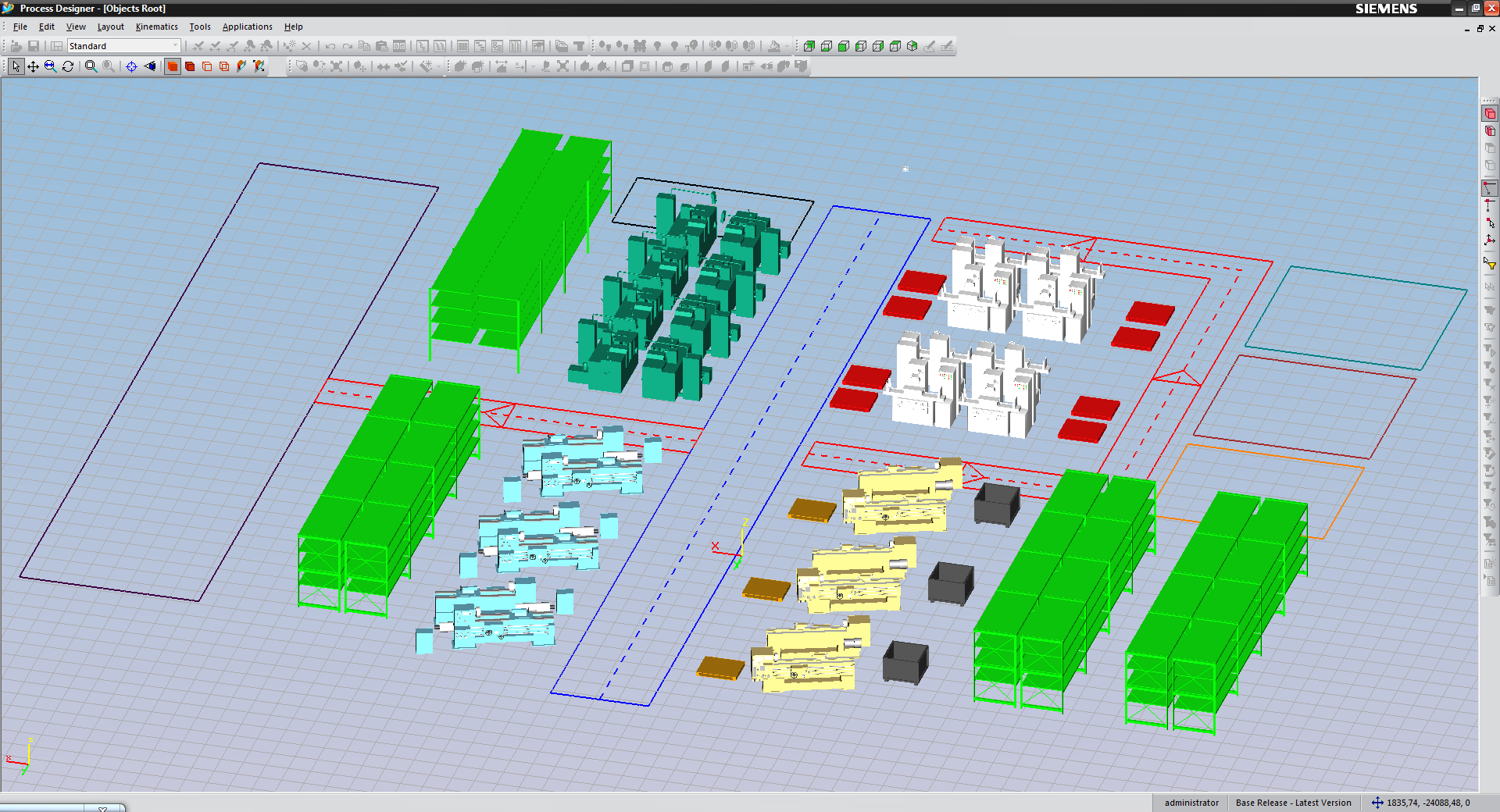

Logistics areas and tracks features enable to build a logistic path network and logistics areas. Logistics planners can describe full area and path networks by drawing areas and tracks and connecting them, using connection points, to other logistic areas or tracks. Using these commands logistics planners can define the direction of the tracks, and to set them as one-way or two-way. Defined path networks can be used as the basis for calculations of route and transport time.

Using basic commands for drawing, deleting, showing and hiding all logistics areas and logistics tracks they can be seen and designed directly in the 3D layout of production system (Fig.3.).

Although many different software applications for the field of logistics exist, human with his knowledge is still the most important element for the successful design and planning of logistics systems. His early logistics analysis and optimal definition of supply chain is a key to the effective logistic processes. But using these technologies, companies can prevent unintended failure in case of improper design of material flows and verify their designs before it`s integration into reality. This paper was made about research work support: KEGA 065ŽU-4-2014.

References

- FURMANN, R., ŠTEFÁNIK, A.: Progresívne riešenia pre podporu projektovania výrobných a logistických systémov vyvíjané v spoločnosti CEIT SK, s.r.o., In: Produktivita a inovácie : dvojmesačník Žilinskej univerzity v Žiline v spolupráci so Slovenským centrom produktivity a Ústavom konkurencieschopnosti a inovácií. - ISSN 1335-5961. - Roč. 12, č. 2 (2011), s. 3-5.

- FURMANNOVÁ, B., FURMANN, R.: Moderný prístup k projektovaniu montážneho pracoviska, In: Technológ : časopis pre teóriu a prax mechanických technológií. - ISSN 1337-8996. - Roč. 4, č. 3 (2012), s. 37-40.

- GREGOR, M. – GREGOR, T. – PATKA, J. 2015. Adaptívne logistické systémy (ALS). In ProIN. ISSN 1339 – 2271, 2015, roč. 16, č. 3, s. 15-17.

- KRAJČOVIČ, M. et al.: Intelligent Manufacturing Systems in concept of digital factory, In: Communications : scientific letters of the University of Žilina. - ISSN 1335-4205. - Vol. 15, no. 2 (2013), s. 77-87.

* Ing. Jozef Hnát, PhD., KPI, SjF, ŽU; e-mail: jozef.hnat@fstroj.uniza.sk ** Ing. Beáta Furmannová, PhD., KPI, SjF, ŽU; e-mail: beata.furmannova@fstroj.uniza.sk